WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The ideal grinder necessary is determined by feed size, feed rate, operating conditions and desired product output for processing. Stedman offers two types of industrial hammer mill grinders that transform the consistency of soft and rough materials by using the pulverizing technique of a hammer mill grinder to produce a finished particle.

Vertical Roller Mill Working Principle. There are many different forms of vertical mill, but the working principle is basically the same. All these forms of vertical roller mill with the grinding roller (or the equivalent of grinding roller grinding parts), grinding roll along the horizontal circular motion on the disc, the vertical pressure exerted on the grinding roller through the outer ...

The die is driven by a motor and the rolls turn only as feed between rolls and die develops friction. To make dry feed particles pliable for close compression and to decrease friction and absorb mechanical heat, water is often added to the feed, either as the formula is mixed or in the conditioning chamber of the pellet mill.

efficiency than horizontal ball mills. Feed FlowRate This parameter is used in conjunction with the feed density and motor power to establish the grinding rate in kWh/ mt. The Vertimill can easily handle a fluctuating flow but it should be monitored and can be varied to achieve required product requirement.

Jan 25, 2011· The mechanics of the system are relatively simple. Two 4inch down tubes run the shelled corn into a 4inch variablespeed auger. That auger feeds the hammer mill and can be set at any speed, based on how hard the corn is. Amperage on the mill is monitored so it won''t overload the motor.. A 6inch auger transfers ground corn from the mill to a 4inch vertical auger, which carries it 32 feet ...

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit. xConsistently high product quality with minimum .

The motor shaft and Vari Drive pulleys are dynamically balanced, then hardchromed this allow a vibration free milling even at high speed Since the Varispeed drive system is operated by sliding the Vari Drive pulley up and down the motor shaft.

Biomass Pellet Mill Flour Mill Cold Roll Forming Food Processing Motor Spindle It is a kind of fine grinder for crushing raw material in feed pelletizing plant It is a vertical type crushing machine for feed milling plant Our company will attend the 116th session .

Dec 15, 2016· In the transverse grinding process a wheel, substantially wider than the actual cross feed, distributes over its face the developed cutting force, thus permitting higher downfeed rates. The cross feed, which is used in traverse grinding only, is commonly selected to equal a specific part of the wheel width, such as 1/4 to 1/12.

Roller mill: Roller mills used for the grinding of animal, pet, livestock, poultry, aquatic and other feed ingredients and grains ... (~23 cm) roll to 3,140 feet per minute (~957 m/min) for a 12inch (~ cm) roll. Usually a single motor is used to power a two high roll pair, with either belt or chain reduction supplying the differential ...

Vertical Mill. Vertical Mill Layout, Alternatives. Vertical mill calculations Symbols Power consumption Grinding pressure Mill internals Nozzle ring Dam ring Heat balances, Example Layout Alternatives There are two basic layouts of the VRM system; product collection in cyclone(s) or product collection in filter. Product collection in cyclone(s):

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and roller mill has many different forms, but it works basically the same.

Machine Accessories Milling Attachments Heads for sale listings We have 27 listings for Milling Attachments Heads listed below. Find items by using the following search options. You can also click on the column heading to sort through the listings. For .

Omas Galileo Plansifter. Bratney Companies | Feed Milling Grinding Equipment. Central supporting framework made of fabricated sheet steel, hanging by means of flexible canes,complete with drive shaft and counter weight supported by two oscillating double row spherical roller bearings

GRINDING FORCES, POWER, AND SPECIFIC ENERGY. Forces are developed between the wheel and the workpiece owing to the grinding action. For plunge grinding operations, as illustrated in Figure 52 for straight surface and external cylindrical grinding, the total force vector exerted by the workpiece against the wheel can be separated into a tangential component F t and a normal component F n.

A milling machine is basically used for shaping, routing, boring, and drilling metals and other solid materials. Generally there are two categories of the milling machine which include the vertical type and the horizontal type. In order to optimize the capacity of the milling machine, it is essential to identify the appropriate milling machine type for specific tasks.

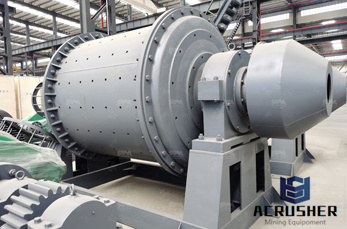

SAG is an acronym for SemiAutogenous Grinding. SAG mills are autogenous mills but use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42'' () in diameter, powered by a 28 MW (38,000 HP) motor.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Hammer mills: hammermills: used in the grinding of animal, pet, livestock, poultry, aquatic and other feed ingredients. ... less energy efficient when compared to a roller mill may generate heat (source of energy loss) produce greater particle size variability (less uniform) ... This type of feeder can have its motor slaved by a ...

Determine the structural design of the vertical roller mill stand and the main parameters. As the state vigorously promote technological innovation and new dry cement design optimization, in order ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY ... process measurements, feed/product characteristics and grinding performance, in order to improve mill output and reduction in power consumptions in the ball mill system. ... production is obtained from a ball mill when the mill motor power is at a maximum and consequently ...

mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential ...

effect of table speed in vertical roller mill vertical roller mill grinding table speed, vertical roller mill grinding table speed speed reducer vertical roller . [More] Product Review: Sieg SX4 MidSize Mill, Power Feed Option With a table as long as this one (32 in, 820mm), a power feed is pretty much a requirement, unless you . price

However, despite a generally good performance of vertical roller mills used for grinding of cement and related products the vertical roller mill is still inferior to the ball mill in terms of sensitivity to variations of mill feed quality (fineness) and mill feed rate. Product quality