WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

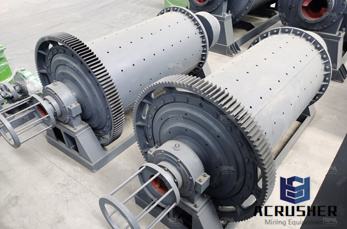

Traditional clinker grinding station adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it will be replaced gradually by vertical roller mill. Great Wall Machinery is the professional manufacturer of cement equipment, can offer complete solution for grinding station, and improves production efficiency, reduces power ...

We developed complete series of clinker grinding unit for sale in India. If you want to know clinker grinding unit cost India or any other information, please chat online with us. Ball mill is a good choice for cement clinker grinding operation. The ball mill grinds ores and other materials to a typical product size of 35 mesh or finer.

In the finish grinding, clinker is mixed with gypsum and other minerals, such as blast Ball mills continue to be the dominating choice for finish grinding, although their Investment costs are estimated to be between US 8 per annual ton Indian Cement Review Magazine, Grinding Solutions. In any project, the concept of grinding clinker ...

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

Nov 23, 2017· Vertical roller mill: * Brand:Shuguang * Parameter:see form * Vertical roller mill is short for grinding, which is used for cement raw material, cement clinker, slag and cinder mill. It has the characteristics of simple structur...

Clinker Grinder Machine Cost in China. ... The cement clinker grinding circuit reduces the feed from 80% passing size between 10 and 20 mm to passing 90 microns. The size reduction takes place in a two compartment tube mill; the first compartment of the mill is shorter than the second compartment. ... Go Back Home | Vertical Roller Mill.

Clinker Grinding Station Great Wall Corporation. Solution Introduction Traditional clinker grinding station adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it will be replaced gradually by vertical roller mill. Chat Online

Ball mills, that are commonly used for finish grinding, have high energy demands, consuming up to 3042 kWh/t clinker depending on the fineness of the cement. Complete replacement of ball mills by vertical roller mills (VRMs) with an integral separator – as opposed to the use of VRMs as pregrinding to ball mills – is regarded as a breakthrough.

Figure 3: H However, despite a generally good performance of vertical roller mills used for grinding of cement and related products the vertical roller mill is still inferior to the ball. Cost Of Cement Clinker Grinding PlantStone Crusher Sale. In some ore processing and production processes, Cement Clinker Grinding Mills are the main milling ...

Cost Of Cement Clinker Grinding Plant What should be paid attention to in the initial stage of Cement Clinker Grinding Machine? Cement Clinker Grinding Machines have been widely used in mineral processing, chemical and building materials industries.

Aug 05, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

for raw meal, clinker and coal grinding due to their lower capital cost and energy consumption compared to ball mills. Loesche , Germany, has been a leading supplier of roller mills for over 100 years and in more recent times, has expanded by adding a subsidiary automation company for both hardware and software delivery and project management.

Dry Process Cement Grinding Vertical Roller Mill For Sale, Find Complete Details about Dry Process Cement Grinding Vertical Roller Mill For Sale,Cement Clinker Price,Grinding Mill For Sale,Vertical Roller Mill from Mine Mill Supplier or ManufacturerXinxiang Great Wall Machinery Co., Ltd.

The grinding process in ball mills and vertical roller mills differ fundamentally. In a ball mill the comminution takes place by impact and attrition. The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the ...

cost of cement grinding mill; cost of cement grinding mill. Cement Ball Mill Price ... vertical roller mill for cement cost price Cement mill Wikipedia, the free encyclopedia. ... ever, the energyintensive clinker grinding process ... costs is possible through the high production rates of.

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process.

Sep 27, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

utilised for the grinding of raw materials, coal and clinker. Various technological improvements from the conventional ball mills in this area include: • High efficiency separators (HES) • Improved ball mill internals • Vertical roller mills (VRM) • High pressure grinding rolls (HPGR) • Horizontal/ Ring Roller Mill

uses the testroller mill Atrol (throughput approx. 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills. Roller mill for granulated blast furnace slag grinding in China. Roller mill for cement raw material grinding in China. Roller mill for cement clinker grinding in Mexico. Coal grinding plant in Poland.

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

Vertical Roller Mills fl. For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality.

Vertical roller mill Application. Vertical mill is dependant on the domestic and foreign sophisticated technology, combined with production encounter in grinding machine. Vertical grinding machine is definitely an ideal device, integrated crushing, drying out, grinding, grading transport together.

Cement Grinding Station application in mine industry, cement plant, large coal processing enterprises and Industrial crushing and grinding. Cement grinding station can make full use of Industrial waste such as the slag, fly ash, furnace slag and coal gangue around the city, so it is an environmental protection industry.