WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS 06 The different manufacturers of vertical mills mainly distinguish themselves in the shape of the grinding rollers and therefore the grinding plate''s profile. The dynamic separators are the same as the ones used on tubular ball mills, obviously adapted to the vertical grinding machinery.

Excessive noise or vibration 16 Seal leakage 20 Section : Alfa Laval ... • Insufficient or no auxiliary flushing services . 7 No or low flow Pump is not primed Centrifugal pumps are capable of evacuating (pumping) a modest amount of air from the suction side of

Mar 01, 2016· re vibration vertical roller mill. There are a number of reasons for high vibrations in vertical roller mills, such as: 1. Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concrete.

Vertical Roller Mills (VRM) have a clearly higher energy efficiency ... compaction and deaeration, resulting in vibration and higher wear of the equipment. Water injection is a common method to overcome these problems, but due to the prehydration of

Vertical roller mills are large grinding machines developed, designed and manufactured by Sinomatec; Sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is .

Vertical Roller Mill (VRM) merupakan salah satu equipment penting yang digunakan oleh PT. Holcim Tuban Plant Indonesia untuk kegiatan grinding material. Vibrasi berlebih yang ditimbulkan oleh VRM menyebabkan operasi VRM harus diberhentikan. Water injection ditambahkan pada VRM sebagai komponen yang mampu mengurangi vibrasi berlebih yang terjadi.

Keywords: vertical roller mill, model predictive control, proportional integral and derivative control, artificial neural networks, fuzzy logic. 1. INTRODUCTION The VRM is a type of grinding mill integrated with multi functions such as grinding, drying and separation, used for .

Lumps and blockages in cement silos have long been an issue at some cement plants. In the 1970s, FL conducted research on ball mills and cement storage that revealed the cause to be an unfortunate combination of insufficient gypsum dehydration in the mill, high silo storage temperature and lengthy storage time.

Jun 16, 2019· 6" production flowline operating at 5 bar and 60 deg C with > 98% watercut failed after 4 years due to Insufficient wetting of fibers during manufacture. Flange on 250 mm diameter piping in oil service directly connected to a pump cracked causing a leak due to pump vibration causing mechanical failure at flange/pipe interface; HDPE:

Centrifugal Pump Vibrations: The Causes by Steven J. Hrivnak, Associate Mechanical Engineer Tennessee Eastman Eastman Chemical Company EASTMAN. FAULTS REPORTED OVER 3 YEARS. Vibration: a measure of reliability! Poorly installed and operated pumps average ... • Insufficient Immersion of Suction Pipe or Bell.

Vertical Roller Mills. Vertical Roller Mills. The term Vertical Mill denotes equipment with the following characteristics A rotating, circular grinding table that turns around a vertical shaft Spherical, cylindrical, tapered rollers that are pressed on to roller paths on the surface of .

Water injection tests. The impact of water injection is explained below. In general water injected on the mill table acts as a grinding aid to increase production and lower power consumption. Water also helps reduce mill vibrations, especially with dusty clinker.

The vibration control of raw material vertical roller mill system News Date: 14:13:26. The vibration of mill body of vertical roller mill is a normal phenomenon exists in working condition, reasonable vibration is allowed, if the mill has a violent vibration, it will cause damage to millstone, roller lining and accessory equipment. . Therefore, vibration values in working condition ...

Home; How to Determine Root Cause of Excessive Pump Vibration. Excessive vibration is a good indicator that some damaging phenomenon could be occurring within a pump, or the immediate pump system, which is why many pump users monitor pump vibration on a regular basis.

Jun 19, 2015· If 75 percent of critical speed is considered desirable for efficient grinding in a meter (8 foot) diameter mill, then the same will be true for a meter (15½ foot) diameter mill.

Typically seals are cooled by water as it passes through the pump. If the pump is dry or has insufficient water for priming it could damage the mechanical seal. Oillubricated and occasionally greaselubricated seals are available on some pumps that provide positive lubrication in the event the pump is run without water.

The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength development ́ Reduced vibration, less wear ́ Reduced water injection, less prehydration

Large vertical roller mill is mostly used in raw meal preparation system. In the process of process production, the vibration of vertical mill has a great influence on the whole process production operation, equipment maintenance and use, equipment spare parts cycle, and sometimes even determines the factors.

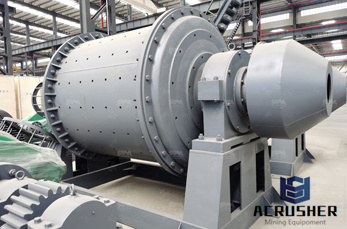

Vertical Roller Mill Summary Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Ball mill vs. vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance Improvement

Royal machine mounts simplify machine installation, reduce noise, and isolate vibration. They are great for all types of machinery, including lathes, mills, grinders, presses, and injection molding machines. Royal machine mounts meet OSHA requirements by preventing machines from "walking" without the need for bolting or cementing.

The most disturbing flow patterns to a pump are those that result from swirling liquid that has traversed several directions in various planes. This swirl could adversely affect the pump by reducing the performance and net positive suction head (NPSH) available. It could also generate noise, vibration and damage in highsuctionenergy pumps.

Aug 08, 2013· feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet duct speed reducer with table bearingand motor clutch grinding table hot gas inlet hydraulic cylinder table liner roller with tyre or segments roller axle rocker arm discharge flap separator tailings cone separator guide vanes cage rotor ...

Spindle power 1500W watercooled frequency spindle Spindle converter 1500W Input Power 220V / 110V power supply Output Current Drive (peak 5A) Drive motor NEMA23 76mm length stepper motors (twophase 4 wire) Net Weight 60Kgs Gross Weight 95Kgs Outside packing 80*70*85 (cm) Vertical CNC Router out aluminum dragon pillar. Features: 1.

Reasons For Vibration In Vertical Mill Pdf. Operational Experience from the United States'' First Vertical . Mill vibration mm/s – Grinding aid % Blaine . PSD from the vertical mill may not exactly match that of the ball mill; however the specific. 12. VIBRATION ISOLATION – MNE